OCCLUSION RECONSTRUCTION OF UPPER JAW USING DIGITAL IMPLANTS AND RESTORATIONS

With a higher level of life quality, people pay more attention to dental health issues. Among them, edentulous patients are a very special group that requires occlusion reconstruction which has been challenging for dentists in the past. Nowadays, with the widespread use of digital technology in implantation and restoration, treatment processes are more effective and less time-consuming, resulting in much greater accuracy and long-term stability. Today’s case about occlusion reconstrcution of upper jaw comes from Dr. Abdelrahman Khalaf and Dr. Kirollos Hany of the Faculty of Dentistry at Assiut University.

Fig 1: Dr. Abdelrahman Khalaf & Dr. Kirollos Hany

Case Profile

Main Complaint

Having suffered from edentulism in the upper jaw for a period of time, the patient experienced difficulties with mastication and pronunciation. Seeking assistance from dental professionals, she aimed to resolve this issue and improve her quality of life

Data Capture and Implant Surgery Guide Making

Upon the patient’s arrival, the dentists obtained multiple data, including DICOM skull data and intraoral data. During this process, two special markers were placed on her palate as indicators to facilitate alignment between intraoral scan data and DICOM skull data in exocad (Fig 2, Fig 3). With this information, the dentist can design the surgery implant guide which ensured precise control over the position, angle and depth of each implant body (Fig 4 and Fig 5). The surgery guide was printed using AccuFab-D1s, an impressively stable printer produced by SHINING 3D.

Fig 2,3: DICOM skull data and intraoral data

Fig 4,5: Design the surgery implant guide

Implantation Surgery Process

With the aid of the surgical guide, the dentist performed the surgery, accurately placing and angling the implant bodies to their intended position and depth. Following several months of recovery, stable osseointegration occurred between the implant bodies and bone tissue, resulting in an optimal emergence profile.

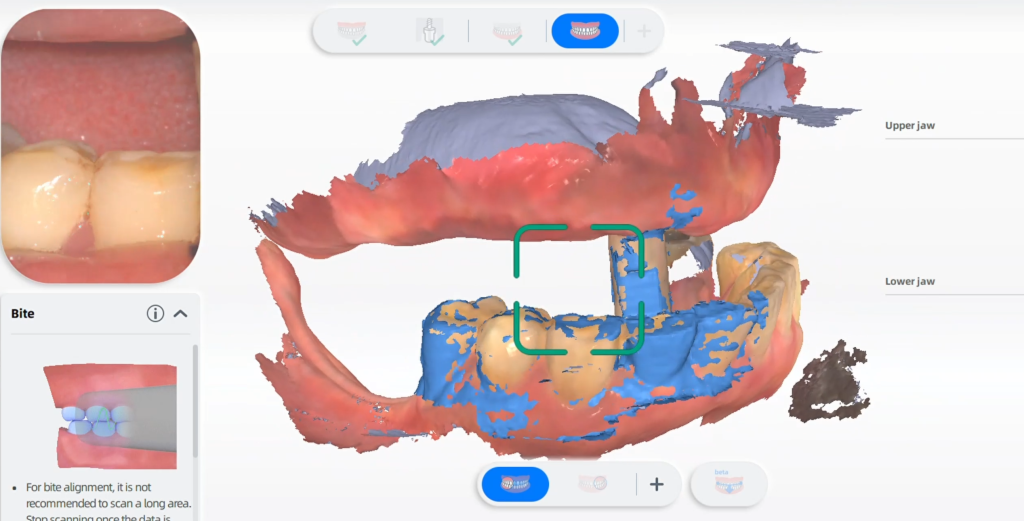

Intraoral Scan Before Making Upper Restorations

The dentist utilized Aoralscan 3 to capture post-implant intraoral data for both upper and lower jaws, as well as occlusion. This highly efficient Aoralscan 3 is capable of accurately capturing data of edentulous cases. (Fig 6, Fig 7, Fig 8, Fig 9, Fig 10).

Fig 6,7,8,9,10: Capture post-implant intraoral data for both upper, lower jaws and occlusion

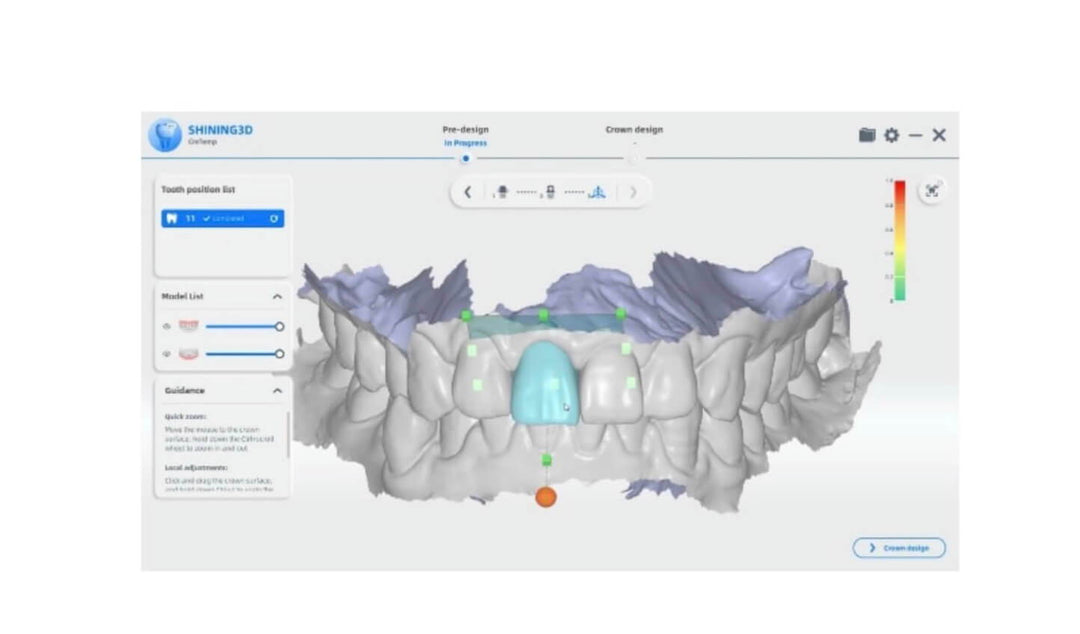

Design Process

The data is imported into exocad for the purpose of designing the final restorations. A total of 12 teeth are divided into two bridges, with one bridge consisting of 5 units from #12 to #16 and the other bridge consisting of 7 units from #11 to #26 (Fig 11, Fig 12).

Fig 11,12: Design process for this edentulous case

Model Printing and Bridges Fabricating

A model was printed for inspection. In the event of any improper restorations being identified during the check, the dentist had an opportunity to make adjustments before the patient’s arrival. The restorations were milled and made by zirconia and exhibited vivid morphology and color (Fig 13, Fig 14).

Fig 13,14: A model was printed for inspection

Final Delivery for Occlusion Reconstruction of Upper Jaw

The final step involves the permanent fixation of the restorations into the patient’s oral cavity (Fig 15, Fig 16). The outcome was met with great satisfaction from the patient as it not only restored her occlusion and masticatory function but also enhanced the aesthetic appeal (Fig 17, Fig 18). The occlusion reconstruction of upper jaw is finished.

Fig 15,16: The permanent fixation of the restorations into the patient’s oral cavity

Fig 17,18: The result of teeth implant and restoration

Comments from Dentist Dr. Abdelrahman Khalaf and Dr. Kirollos Hany

We are dedicated to the implant dentistry industry and have witnessed how digital technology has revolutionized implant treatment, transforming it from a freehand operation to a guided procedure, from physical impressions to digital ones, and from handcrafted temporary crowns to 3D-printed resin crowns. SHINING 3D’s products, especially in the occlusion reonstruction of upper jaw, have played an instrumental role in driving this transformation, and we are thrilled to embrace the digital future with their support.

Leave a comment